Are bakeries calculating their profits correctly?

Bakers have good insight into the profitability of individual customers and products, but, for many, this is often based upon product margins worked out against list price.

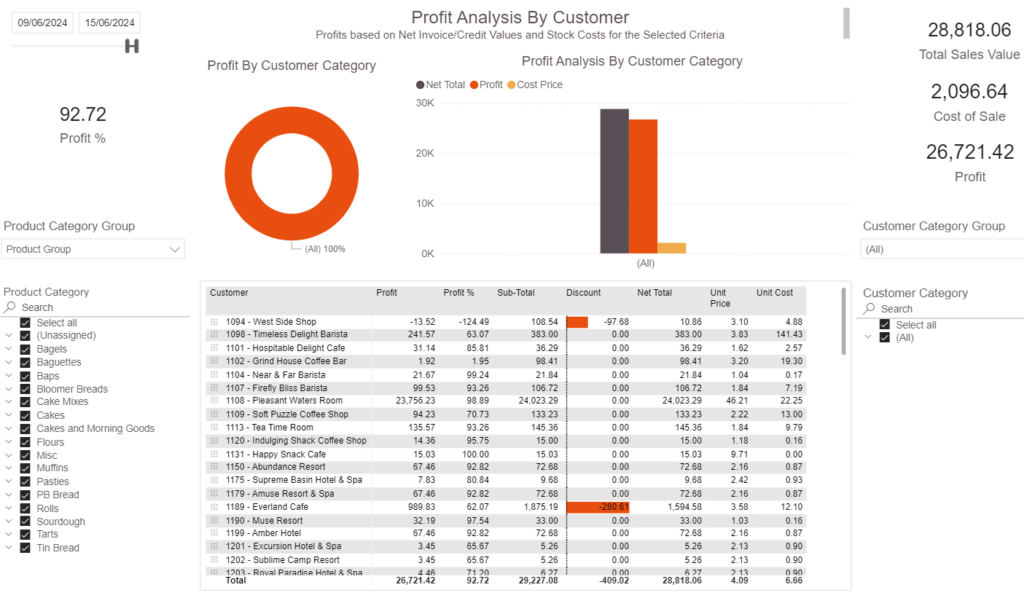

Unless all their customers are on the same price list, the reality can be quite different once invoice discounts, customer-specific pricing and order volumes for each product are considered.

When evaluating the value of each customer account, many businesses tend to focus on sales values rather than profitability. This is mainly, it has to be said, due to difficulties in reporting upon profitability. However, when their focus does change to profitability, the view of who their most important customers are often changes.

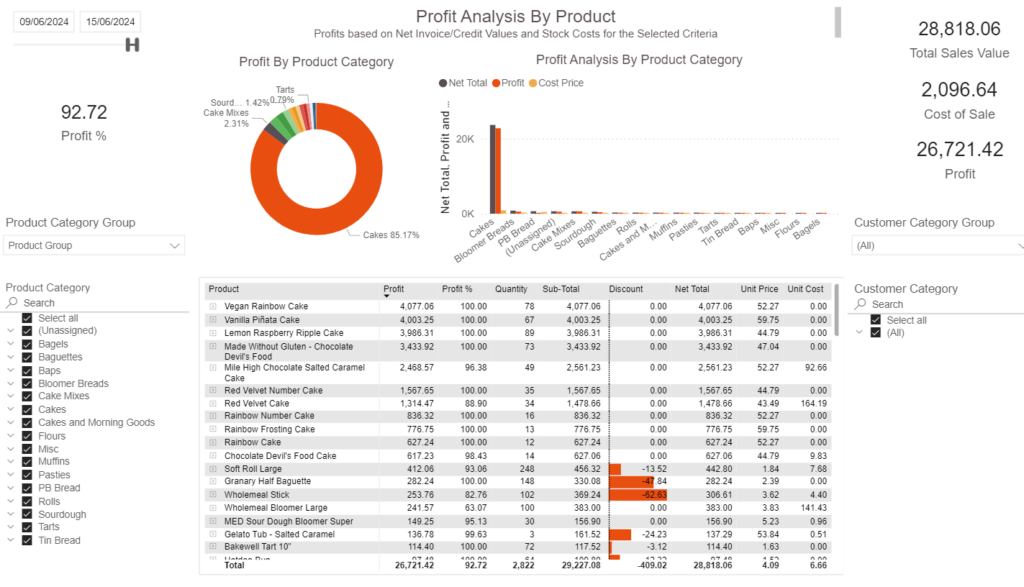

In the case of product profitability, many bakeries do not have the systems in place to report on the actual gross profit (GP) generated by each product, i.e. at invoiced values. Instead, each product is either evaluated based upon weekly sales values, or the GP is calculated based purely on the GP achieved at list price.

Unless all customers are charged the same price for a product, then reporting on profitability at invoiced values will lead to better-informed decision making. When commercial bakeries start to look at product profitability in this way, it isn’t unheard of them to uncover some products that are selling at a loss.

For either customer or product profitability reporting to enable better decision making, accurate costing of every product is essential. To do this, both the cost prices of ingredients and the method of costing need to be accurate and always kept up to date.

To ensure ingredient prices are always up to date, a purchasing process that is fully integrated with your recipe costings is highly desirable. That way, all cost prices are always current.

Time-consuming

Where recipes costings are maintained on spreadsheets, there is a time-consuming process involved in keeping ingredient prices up to date. This potentially delays getting information ready to carry out price reviews on bakeries’ products which, in turn, holds up any price increases that they may need to make.

The simplest method used by bakers to cost products is to aim to achieve a given uplift on ingredient costs.

For example, this might be aiming to sell the finished product at 5x the cost of the ingredients used to make it (i.e. 80% GP). If all products take similar amounts of labor to make, then this is a fair approach to take.

However, if a bakery is making products with significantly different amounts of labor input, then this approach is inadequate.

For instance, the ingredient cost of a jam donut and hand-decorated donut might be similar, but the labor required for a craft baker to make a hand-decorated donut will be far higher.

A more comprehensive approach to costing is to include all direct costs for making products. This can be taken as ingredient, packaging and labor costs, but could also include an allowance for direct energy costs, tray papers, and so on.

This method gives a more accurate measure of the GP generated by each product, and often highlights labor-intensive products that are not generating a high enough GP.

Sophisticated

The most sophisticated costing method is when an allowance for overheads is also apportioned to each product. Generally, it is only larger bakeries with management accountants who try to practice this ‘dark art’.

For bakers to have confidence in their reporting of both customer and product profitability, a robust reporting system must be in place.

Until recently, for many bakeries this would require a skilled accounts team doing the expensive and time-consuming task of keeping multiple sets of data updated. And at times when ingredient prices are highly volatile, keeping costings up to date becomes even more time-consuming.

In recent years, specialist high powered systems such as ours have emerged that offer solutions to streamline this type of business reporting. For example, by placing orders for ingredients through Cybake’s purchasing module, ingredient prices, recipes and product margins are always up to date.

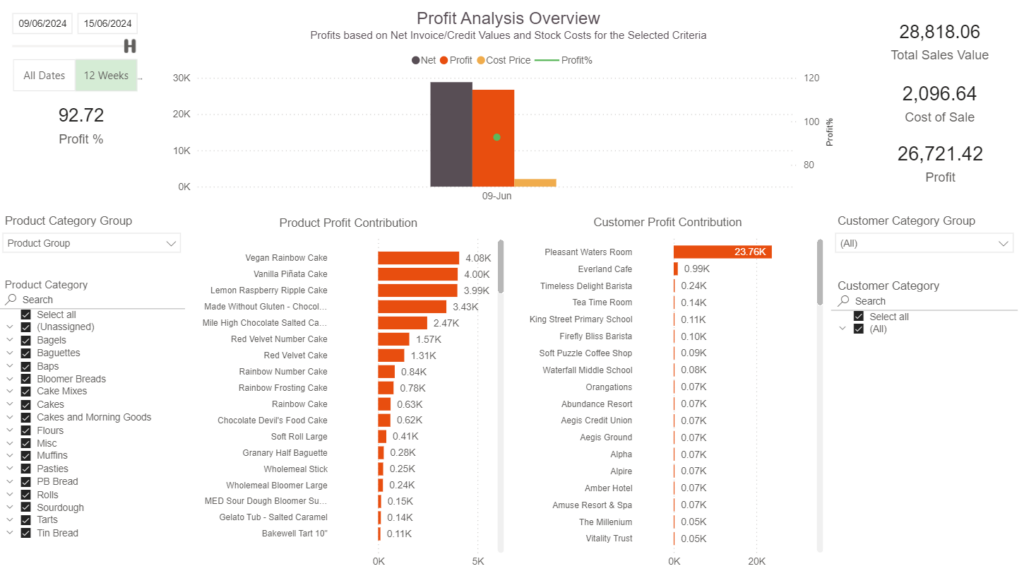

Cybake then uses Microsoft Business Intelligence for direct product and customer profitability reporting that is available at the push of a button (see screenshots below). No more delays waiting for cost prices to be updated before you can review margins and put a price increase through.

“Sales are vanity, profit is sanity”. It’s a well-known dictum that’s not easily adhered to without the right management and reporting systems in place.

Profit by customer report

Profit by product report

Overview

If you think your bakery could benefit from Cybake’s cutting-edge business analytics, why not get in touch for an online demo?